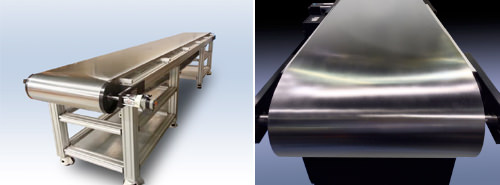

Belt Technologies Wide Belts: a unique combination.

Belt Technologies Inc. has been manufacturing metal belts and conveyors for many different kinds of specialized projects in different industries around the world for many years. As specialists in steel belt-based conveying, such application diversity allows us to work with equipment suppliers and end users to provide individually customized, turnkey solutions based on the most demanding customer’s specific processes and technical requirements. One of our core strengths that differentiate us from any other belt manufacturer is our unique ability to produce Wide Belts utilizing very thin material typically 0.076 mm – 0.4 mm. Traditionally, wider belts are often offered with thicknesses of 1 mm or more which means working with pulley diameters in excess of 800 mm. These thin materials can pass on some important benefits to our customers which can translate into significant cost savings and potential competitive advantage over other machinery.

- Belt Technologies’ unique advantage is the ability to process very thin materials (thicknesses 0.076 mm. – 0.4 mm) in wider widths (up to 900 mm).

- By using thinner steel materials, smaller pulley diameters can be used, saving space with a smaller overall machine footprint and achieving reduced inertia which means saving costs in drive systems, decreasing energy usage to operate the systems.

- By decreasing material thickness we improve heat transfer properties that solve thermal issues in many applications, such as in the cooking of food products.

- By decreasing footprint, the end user can save space at the processing site which is critical in the case of frozen foods and refrigerated areas.

- By using thinner and lighter materials, the complexity of belt tensioning and tracking devices are simplified.

- Wide Belts made of thin stainless steel means conveyor belts can be cleaned and sanitized significantly faster, with easy access, ensuring high availability – important in multi-shift operations. Shortened cleaning times also represent lower costs and ecological best practices, with low water consumption and low use of milder detergents and other cleaning agents.

- Wide Belts made of thin stainless steel can be used for many different applications.

- Coated Wide Belts for casting applications.

- Food applications of wide stainless steel belts at different temperatures.

- Tracking devices can be used more effectively by using thinner material.

Stainless Steel Conveying advantages in food related applications

Stainless steel remains free of rust because of the interaction between its alloying elements and the environment. Iron, chromium, manganese, silicon, carbon and, in many cases, significant amounts of nickel and molybdenum contained in the stainless steel alloy react with oxygen producing a very thin corrosion resistant film. This film acts as a barrier between outside agents (oxygen/water) and the underlying metal surface, minimizing corrosion. The introduction of stainless steel conveyors for food applications remains the state of the art technology for applications ranging from meat and fish cutting and deboning to ice cream production, cake and cookie baking , fruit and vegetable processing , pet food manufacture and a host of other food related applications.

For some applications, like the one shown below using Belt Technologies wide coated belts, the thermal properties of steel are key to its use. This application illustrates the belt’s ability to conduct heat and operate in different conditions, whether intense hot, cold or humidity.

- Greener, Cleaner cooking with Belt Technologies Wide Belts

- Cooking bacon with Belt Technologies Wide Belts (with FDA’s approved coating)

- Stainless steel’s chemical and bacterial neutrality is ideal in food applications because it poses no threat to either human health or to the taste of food. Durability and corrosion resistance make stainless steel systems last for many years.