Vacuum Conveyor Belts & Vacuum Conveyor Systems

Belt Technologies is the world’s leading manufacturer of complete vacuum conveyor systems utilizing stainless steel perforated metal conveyor belts. Vacuum conveyor systems by Belt Technologies incorporate the advantages of stainless steel metal conveyor belts, which are virtually unstretchable, operate without lubrication, and minimize variations in surface speed for increased efficiency and throughput.

Stainless steel vacuum conveyor belt systems have a high strength-to-weight ratio and provide precise positioning control, making them a superior conveying method for a variety of industries.

Vacuum Conveyors are Ideal for a Variety of Automation Applications

Metal belt vacuum conveyor systems can be found in automated facilities for a wide range of applications. These applications include, but are not limited to:

- Printing

- Pick and place equipment

- Food processing

- Clean room environments where no particulates are permitted

- Elevation changes

- Conveying parts

- Precision Indexing

Belt Technologies provides high-performance stainless steel vacuum belt conveyors for the production of solar cells, which can increase the throughput efficiency of solar panel production.

Vacuum transport with steel belt

Vacuum Conveyor Belt Engineering

Engineers at Belt Technologies have the knowledge and experience to design and fabricate complete vacuum metal belt conveyor belt systems based on your specifications and product requirements. All of our vacuum conveyor systems provide accurate part positioning as well as smooth motion control and indexing. Combined with the beneficial properties of stainless steel perforated metal belts, vacuum conveyor systems are:

- Resistant to rust and corrosion

- Easy to maintain

- Clean and inert

- Resistant to extreme high or low temperatures

- Free from particulates

- Virtually unstretchable

Belt Technologies engineers design custom metal vacuum conveyor belt systems that are able to withstand a range of demanding production environments.

Complete Vacuum Conveyor System Manufacturing

Perforated metal vacuum belts provide a hard, smooth, flat surface that’s ideal for processing, printing, and inspection. Because stainless steel metal conveyor belts do not generate particulates, manufacturers can increase product throughput with less downtime spent on cleaning or removing debris buildup. As a result of customizable perforation patterns, perforated metal belts provide a level of precision and accuracy not attainable with traditional systems.

Belt Technologies manufactures and assembles complete vacuum conveyor systems in ISO-approved, state-of-the-art facilities to ensure the products are functional within strict quality-control parameters.

Steel belt vacuum conveyor

Precise Perforation Techniques for Endless Metal Belts

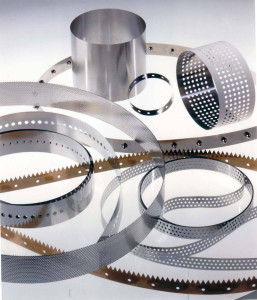

Perforated metal belts are flat, endless metal conveyor belts manufactured with precision perforations. Perforations in a metal belt allow for the passage of air drawn through grooves in the vacuum plenum of the conveyor. This creates a suction effect that will hold flat product materials to the belt surface for maximum positioning control.

Perforated metal belts are flat, endless metal conveyor belts manufactured with precision perforations. Perforations in a metal belt allow for the passage of air drawn through grooves in the vacuum plenum of the conveyor. This creates a suction effect that will hold flat product materials to the belt surface for maximum positioning control.

Our stainless steel conveyor belts are designed and manufactured based on the specific needs and specifications of our customers. A variety of different perforation patterns and sizes are possible. Our engineers can provide design feedback and technical support to ensure the maximum efficiency of your perforated metal conveyor belt.

We use a variety of perforation methods based on the dimensions of the belt and the operational requirements of the vacuum conveyor system. Methods include high-impact mechanical punching, chemical etching, and laser cutting.

Coating and Surface Treatment Options for Vacuum Conveyor Belts

Coatings and surface treatments for perforated metal conveyor belts are also available. Our engineers will help you determine the right coating and product requirements for your system.