When designing conveyor systems for applications involving extreme temperatures, special consideration must be given to the belt materials, the benefits of coating options, the feasibility of maintenance, and even the materials used for pulleys and tracking guides. Belt Technologies has the knowledge and experience to help you choose the right materials for your high- or low-temperature application.

Designing Conveyor Systems for High- and Low-Temperature Applications

Neoprene, rubber, and other common conveyor belt materials can be unsafe to use in extremely high or low temperatures. Neoprene, for example, can withstand temperatures only as high as 200℉. If temperatures exceed this threshold, the material will begin to exhibit signs of thermal decomposition, which include melting and the release of irritating gases. Conversely, temperatures below 0℉ will cause neoprene belts to harden until they are nonfunctional.

Stainless steel, however, has established itself as a durable, versatile, and sanitary conveyor belt material able to withstand a wide range of extreme temperatures. Various stainless steel alloys exist that will maximize a conveyor belt’s ability to function in higher or lower operating temperatures. Belt Technologies also offers a wide range of belt-coating options that can fulfill the unique requirements of a given system.

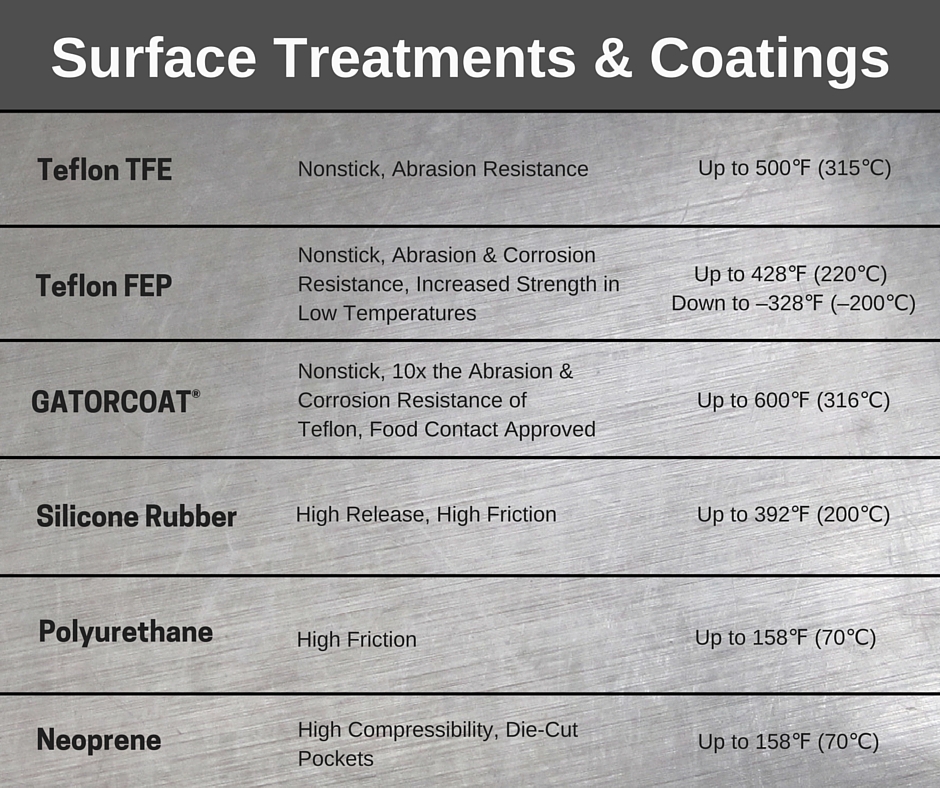

Coatings include but are not limited to:

High-Temperature Conveyor System Design

Activities like cooking or sterilization require a conveyor belt that will resist warping at high temperatures.

For extremely high temperature applications, the effect of thermal expansion on the system is an important factor that must be mitigated. During operation, the equipment will likely begin at a relatively cool ambient temperature and then be brought up to the heat intensity required to cook, solder, or otherwise process the product being transported. The belt must then be able to transition back down to an ambient temperature, or in some cases, down to a freezing environment. If unaccounted for, the effect of expansion and contraction in the system can have a negative impact on belt timing, tracking, tension, and surface flatness.

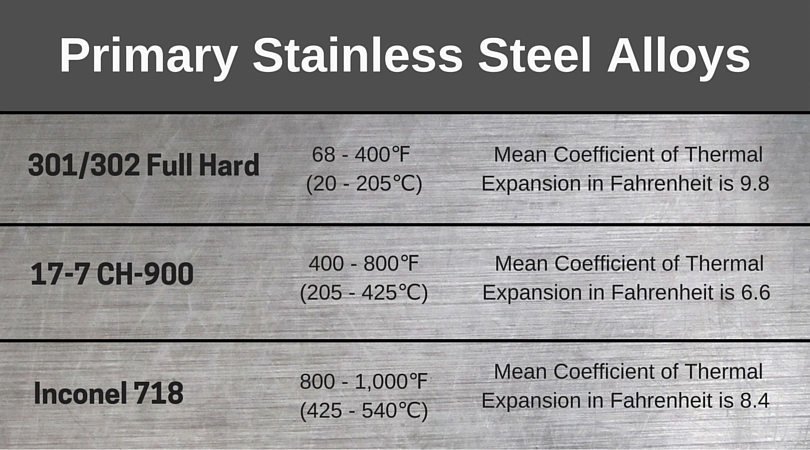

Material selection for the conveyor system will depend on the level of heat the belt will be expected to withstand. Some systems, such as solar panel stringer equipment, will be expected to endure temperatures exceeding 700℉. There are many different alloy compositions of stainless steel that have different coefficients of thermal expansion. Belt Technologies engineers can help you choose the right alloy for your application.

Various coatings or surface treatments, such as GATORCOAT®, can be applied to maximize a belt’s resistance to high temperatures while maintaining optimum release qualities. This facilitates product release from the belt surface.

Any metal exposed to extremely high temperatures will eventually deform, warp, or expand. The engineers at Belt Technologies can assist in choosing the right alloy to achieve optimal belt performance while minimizing deformations. This allows the system to operate for the maximum lifespan of the conveyor belt while requiring minimal downtime for repairs or maintenance. Typically, Belt engineers will recommend stainless steel alloy 17-7 CH-900 due to its very low thermal expansion coefficient, which enables it to endure high temperatures. When temperatures are very high and the warping of the material must be kept at a minimum, other options may include Inconel or Invar alloys

Belt engineers will help you design a conveyor system that accounts for every aspect of the high-temperature system, including expansion joints, fasteners, finishes, all while assuring easy cleaning and maintenance.

Low-Temperature Conveyor System Design

Low-temperature conveyor system applications include the transportation of frozen foods such as meat, fish, ice cream, and some pharmaceuticals that require refrigeration. These systems may require temperatures as low as –25℉. With exceedingly low temperatures, the risk of brittleness in the belt material becomes a major concern. Choosing the right alloy and belt thickness can minimize stiffness in the conveyor belt and prevent breakage.

Low temperature applications, such as freezing processed foods, require materials that will not seize up or become brittle when exposed to extreme cold.

At low temperatures, the impact resistance of system components and the viscosity of the product may introduce unique challenges. Lubricants can thicken and freeze, causing equipment to seize. Stainless steel conveyor belts require no lubrication. Belt Technologies engineers can work with you to design a system that will withstand cold environments effectively.

Maintenance is another factor that should be taken into account when dealing with exceedingly cold environments such as refrigeration units. Unexpected shutdowns can be costly, requiring certain products to be maintained at a freezing temperatures to prevent unnecessary loss. However, performing maintenance in refrigerated environments poses a significant risk to employee health and safety. Belt Technologies manufactures low temperature-resistant conveyor systems that have been designed for quick changeout and sanitization; many maintenance tasks can be performed outside of the freezer whenever possible.

Summary

Whether you are seeking to design a conveyor system for exceedingly high temperatures, freezing temperatures, or a combination of both, Belt Technologies engineers have the knowledge and experience to help. Solid, stainless steel conveyors are available in alloys that provide the optimal range of temperature resistance for any application. Belt performance can be further enhanced with a variety of surface treatments for high-quality product handling. Contact the experts today for comprehensive guidance in designing the perfect high- or low-temperature conveyor system for your application.