Belt Technologies | Бер 27, 2018 | Case Studies

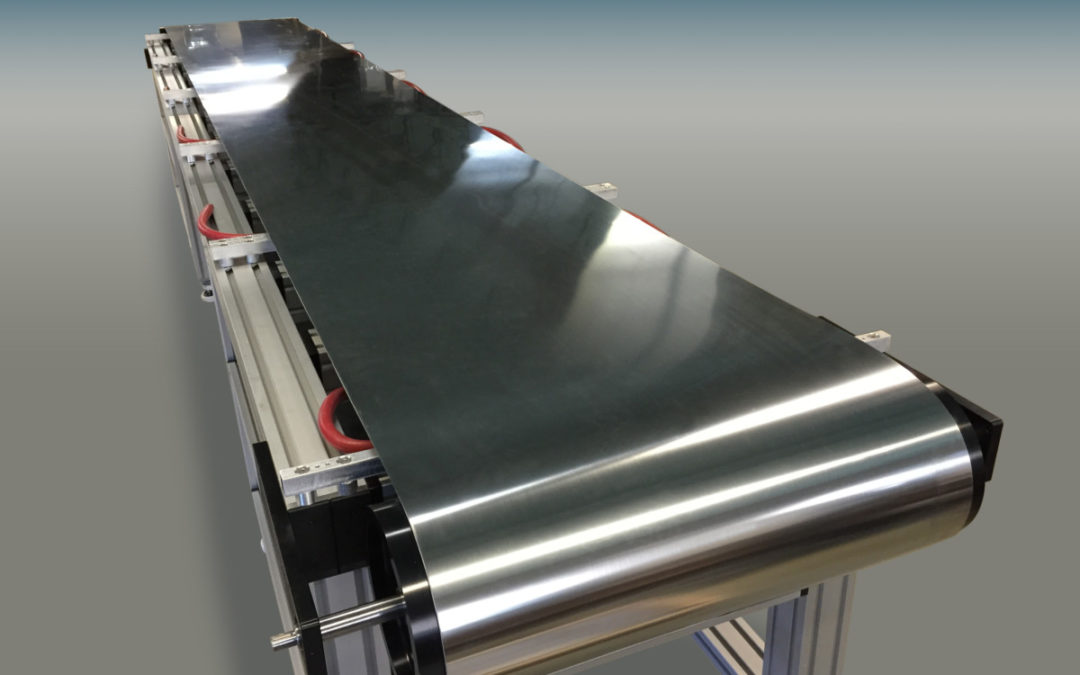

A stainless steel belt is considered “wide” when it is between 22 to 35 inches in width. Wide belts require particular consideration to produce and are traditionally made with thicknesses of 1 millimeter or greater to preserve belt integrity. At Belt Technologies, one...

Belt Technologies | Бер 2, 2018 | Case Studies

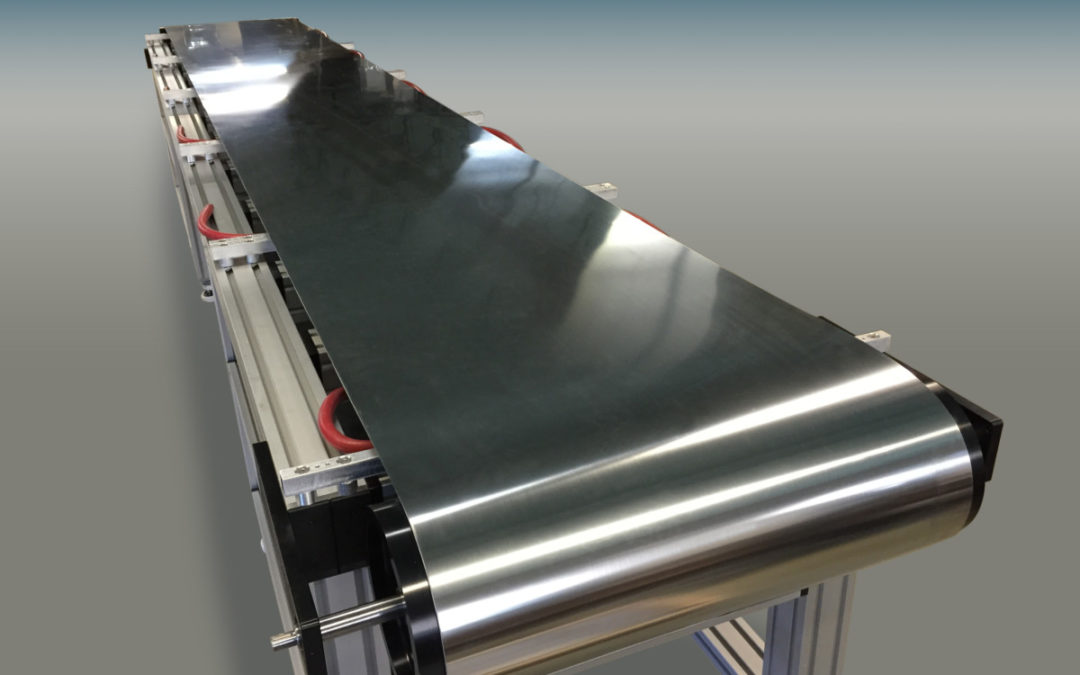

Stainless steel conveyor belt systems are ideal for the cooking, freezing, and handling of edible products. They are versatile and can easily be customized for any automated food processing system with exceptional results. Metal conveyor belts do not outgas and do not...

Belt Technologies | Бер 2, 2018 | Case Studies

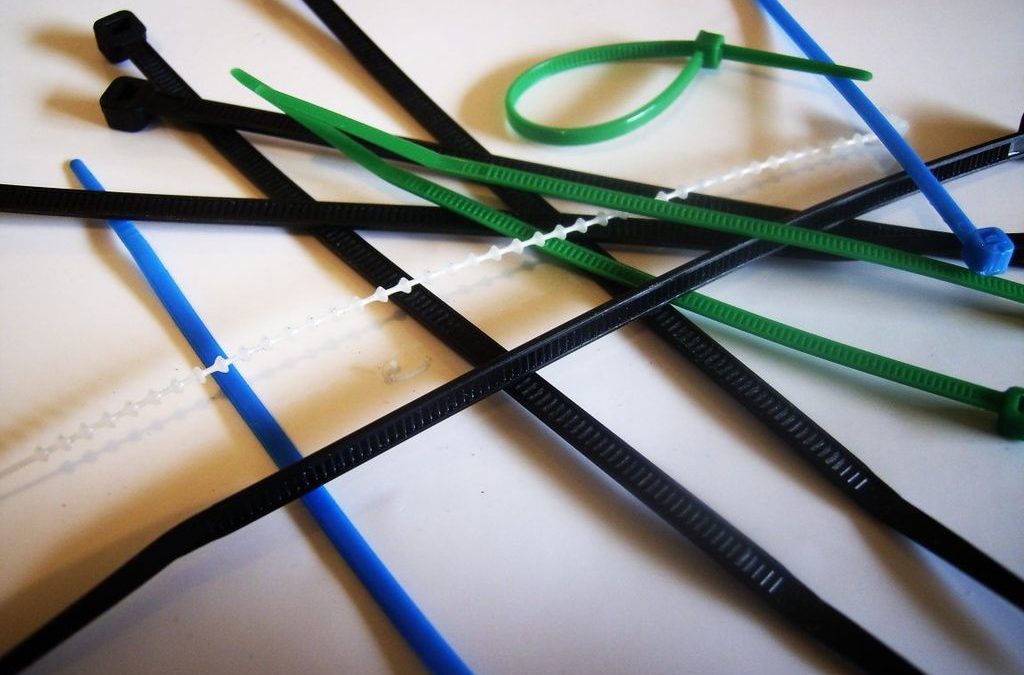

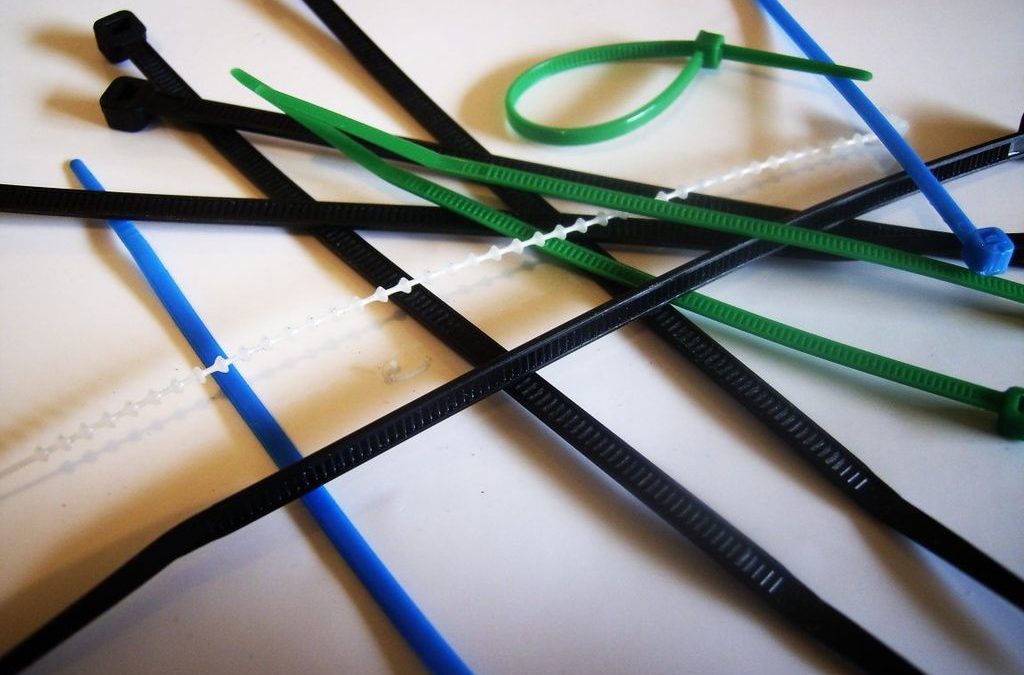

A customer recently approached Belt Technologies seeking a solution to their product handling challenge. The customer produces electrical components including sensors, fiber optics, power systems, cable assemblies, and electrical connectors. They were working on...

Belt Technologies | Жов 13, 2017 | Case Studies

A distributor approached Belt Technologies seeking replacement parts for an automated spray machine used in industrial paint applications. These large machines generally use as many as ten different metal belts for various tasks. Up to seven of the belts operate in...

Belt Technologies | Жов 10, 2017 | Case Studies

A machine-building firm recently approached Belt Technologies with a project to design and produce a highly specialized automated conveyor system. The customer, who had many years of engineering experience, had been tasked with developing new capital equipment for an...

Belt Technologies | Лип 11, 2017 | Case Studies

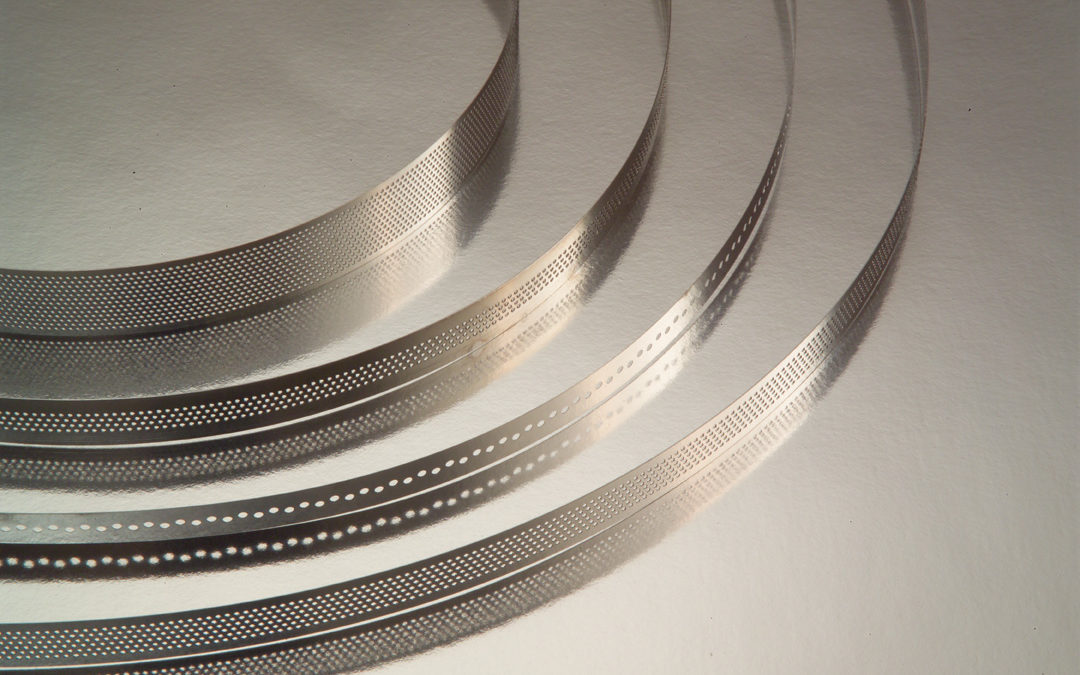

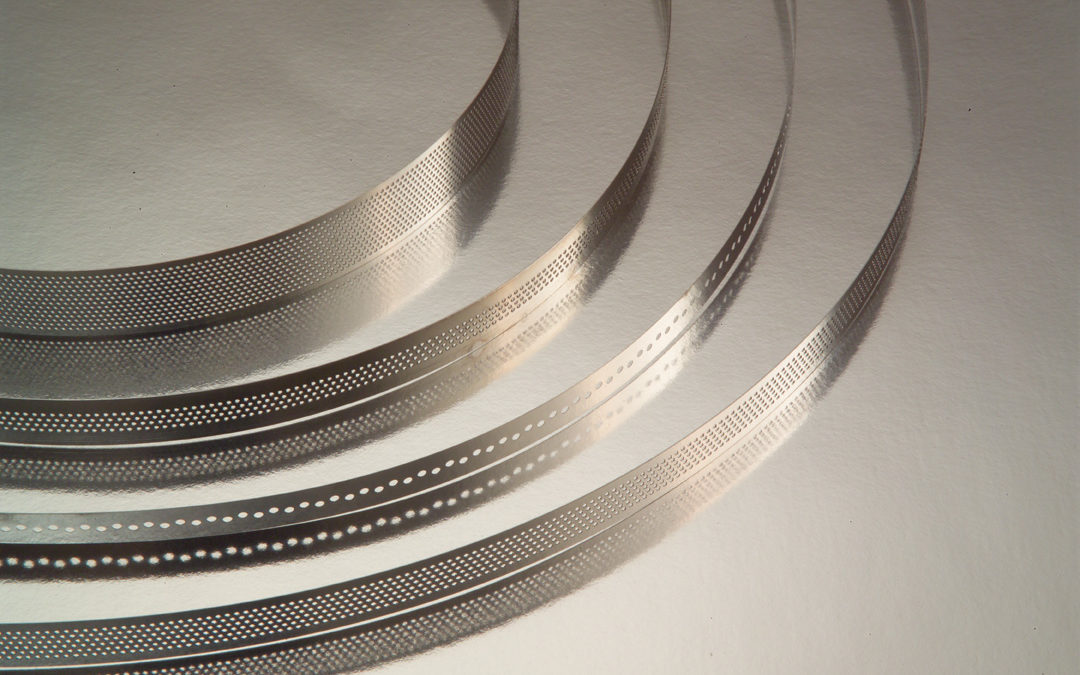

Recently, a major automation OEM producing capital equipment for high-tech industries approached Belt Technologies in need of a custom perforated stainless steel conveyor belt for an automated pharmaceutical assembly system. The client specializes in complex...